Pressing machine Nico 4 was built to press the tip of the tie, working with independent pressing plates with easy and fast replacement, double locking system with vacuum and tiny sheet plate.

Provided with an internal steam generator with low energy consumption.

Extremely easy to use, through an user friendly touch panel that interacts with the central CPU and all the electronic devices, it allows to program the pressing process in order to obtain the best result according to the kind of fabric.

Four adjustable lasers beam helps during the placement of the tie on the pressing plates for high quality pressing of the edge.

The machine can press the open and close ended tie and also seven folded.

Solid structure , high quality controls and components make the machine reliable over time.

| GENERAL FEATURES | |

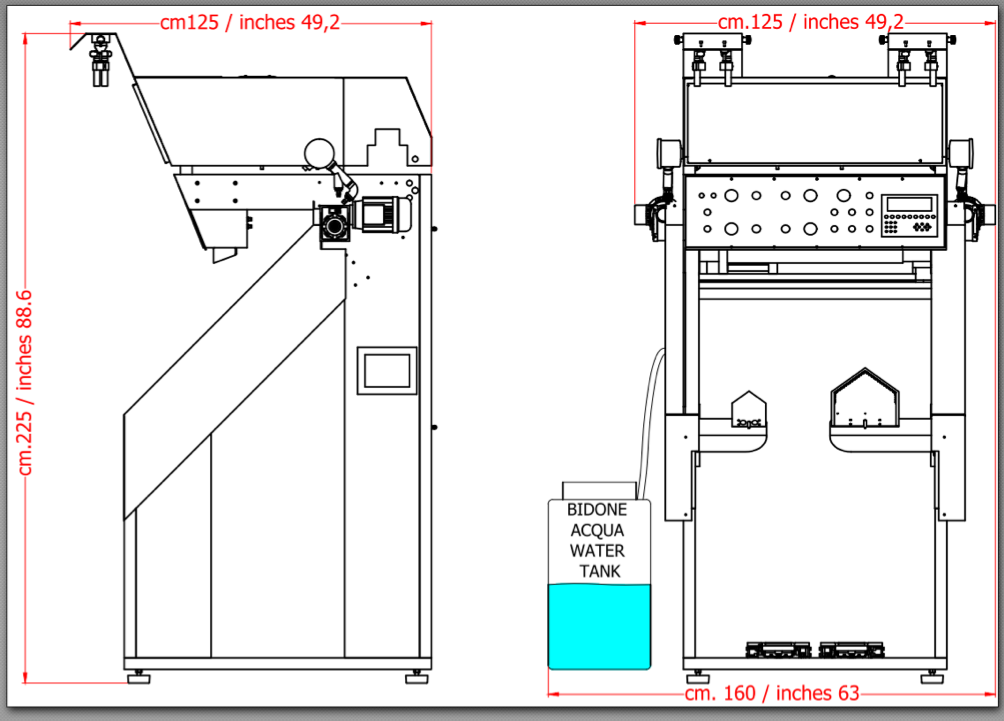

| MACHINE DIMENSIONS | Width cm.125 – Length cm.125 – height cm.225 |

| TOTAL OCCUPIED AREA | cm.160X cm.160 |

| MACHINE WEIGHT | kg.850 |

| LINE VOLTAGE | 400V 50Hz 3 N+G Standard others on request |

| CONTROLS POWER SUPPLY | 24VDC |

| POWER CONSUMPTION | 7KVA (indicative) |

| COMPRESSED AIR LINE PRESSURE | 5,5/6 Bar 85Psi |

| AIR COMPRESSED CONSUMPTION | 42 l/min |

The machine is provided with servo-assisted motors controlled and run by the central CPU.

The machine is operated by a programmable logic controller (PLC) that manages the various phases of the cycle: the pressing times, the count of the pieces and the performance of self-diagnostic tests for errors. All these functions are managed through the LCD panel.

Equipped with four laser devices to helps during the positioning of the tie on the plates.

Fifteen pressing programs, for all the kind of fabrics, easy to set from the LCD panel, with immediate response to the finished work.

Independent pressing plates, so can works with different pressing program for the small or the big.

Fast replacement of the pressing plates.

High productivity.

Low maintenance.

A remote-control kit allows to get in touch with the remote assistance system.

Thanks to interconnectivity to the computer system, instructions or software parts can be uploaded; moreover, it can be easily integrated with other machines of the working cycle

A remote-control kit allows to get in touch with the remote assistance system.

Thanks to interconnectivity to the computer system, instructions or software parts can be uploaded; moreover, it can be easily integrated with other machines of the working cycle

Thanks to many years of experience all the machinery product by Frigerio e Corazza are designed built to satisfy the highest demands of the modern market.

The average is more than 2000 tie every 8 hours.

The two pressing plates are independent ,so the activation and programs are controlled separately to optimize the working cycle and the appropriate pressing program for the small and for the big ends of the tie.

Through a switch placed on the main panel is possible to choose the ironing method, with steam or dry ironing.

All ordinary maintenance is easy and can be carried out by workers with basic mechanic and electric knowledges.