The tie turner is the perfect machinery for the turning of the tie after the lining has been stitched to the tie.It has been projected keeping unchanged the construction features and production quality, of the previous model “GIO, adding more functions to meet the recent production demands.All the machinery produced by Frigerio e Corazza are pratical, functional, easy to use and very little maintenance.

Main features:

| GENERAL DATA | |

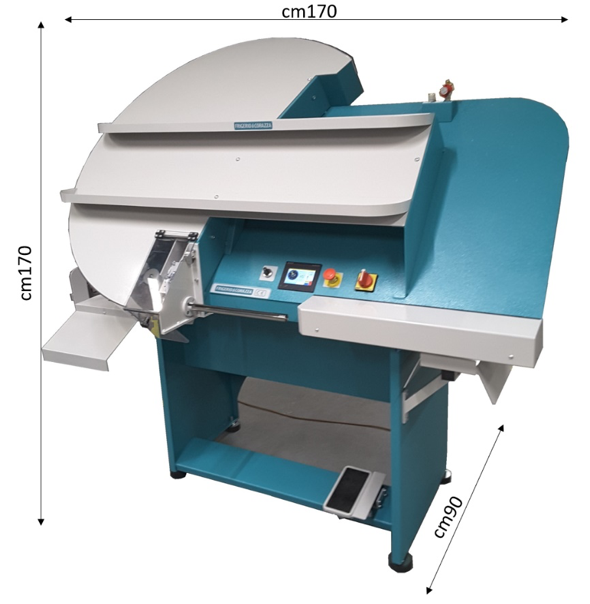

| MACHINE SIZE | Length cm.170 width cm.900 height cm.170 |

| TOTAL OCCUPIED AREA | cm.270Xcm.180 |

| MACHINE WEIGHT | kg.350 |

| LINE VOLTAGE | 400V 50Hz 3 fasi + neutro + terra |

| CONTROLS POWER SUPPLY | 24VDC |

| INSTALLED POWER | 0.4KVA (approximate) |

| COMPRESSED AIR PRESSURE | 5,5/6 atm 85PSI |

| COMPRESSED AIR PRESSURE CONSUMPTION | 25 l/min |

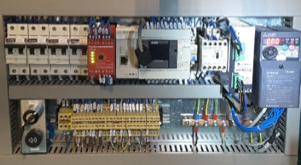

| MAIN COMPONENTS | European production of motors and components, touch screen, PLC, inverter, Mitsubishi, pneumatic SMC. |

| DECLARATION OF CONFORMITY CE |

2006/42ce TIPE “a” MACHINERY DIRECTIVE |

The main motori that moves the reverse armi is actionated by a frequency converter and controlled by an encoder both run by the PLC unit.

The speed of the reversing arm is adjustable through the potentiometer, it allows to adapt the speed according to the consistency of the tie fabric.

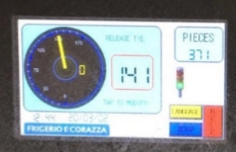

The release of the reversed tie is programmable, setting the stroke through the touch panel, in order to deposit tidy the ties on the tray.

The replacement of the reverser tube is quick and easy trough two screws. Reliable mechanics special maintenance free.

A remote-control kit allows to get in touch with the remote assistance system. Thanks to interconnectivity to the computer system, instructions or software parts can be uploaded; moreover, it can be easily integrated with other machines of the working cycle.

The replacement of the reverser tube it take place through two screws, making the change over quick and easy.

The replacement of the reverser tube it take place through two screws, making the change over quick and easy.

The machine is supplied with three tubes, the dimensions has to be defined following the client requirements.

More than three reversing tubes are not included, must be considered extra supply.

The speed of the arm can be adjusted through the potentiometer placed on the left of the touch screen panel.

The speed adjustment allows to adapt the reversing speed in accordance to the consistency of the tie or to the fabric characteristic.

The unloading of the reversed tie on the holder can be adjusted according to the lenghth of the tie.

Setting directly from the control panel, or through the control panel following a simple step by step program.

The touch screen allows an easy communication between the operator and the machine.

The device displays the numbers of ties sewn, the release position of the arm set, time and date.

It reports any anomaly or failure it may occur.

| TIE HOLDER | FINISHED TIE HOLDER |

|

|

| Huge extensible holder to deposit the ties to reverse. | Huge extensible holder where the revesed tie are released. |

The machine has been certified in accordance with the current European law.

All the components reflect the high quality and reliability of the machine.

|

|

|